Field Test Service

Hydrostatic, pneumatic and hardness test for pipe, boiler tube and storage tank.

Description

Hydrostatic test for piping and boiler tube (up to250 bar).

Also called hydrotest, is a test conducted by pressurizing water into pressurized chamber of test subject such as piping, vessels or boiler tube system

Pneumatic test for pipe and storage tank (up to1000 psi).

Also called air leak test, is a test conducted by pressurizing air into piping system (test subject). To check leak, liquid soap may should applied on area to be check and any leak will be appear as bubble

Hardness test for piping & boiler tube (digital with measuring unit Hardness Brinell)

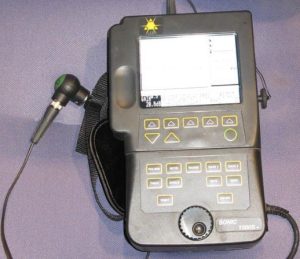

Ultrasonic test

To check thickness and damage (crack) inside wall thickness of piping, tank &vessel.

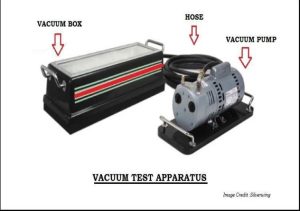

Vacuum box test for flat surface (example:on bottom side of storage tank)

To check leak on welding joint by applying soap on to welding and close it withbox and depressurize it to negative pressure (vacuum). Leak indicated by bubble